Get Quotes

Download Full Catalogue

Model:CNME060301

Use:

The product utilizes saturated steam to rapidly and efficiently sterilize articles. It can be used in hospitals, public health centers, health stations, clinics in factories and mines, scientific research institutes, etc, to sterilize medical equipment,surgical dressings, glass utensils, solutions, substrata. It can also be used as cooker in plateau areas and be used to make high quality drinking water in industrial and mining enterprises.

Characteristics:

Fully stainless steel structure.

Double scale indication pressure gauge.

Electric heated.

Easy to operate, safe and reliable.

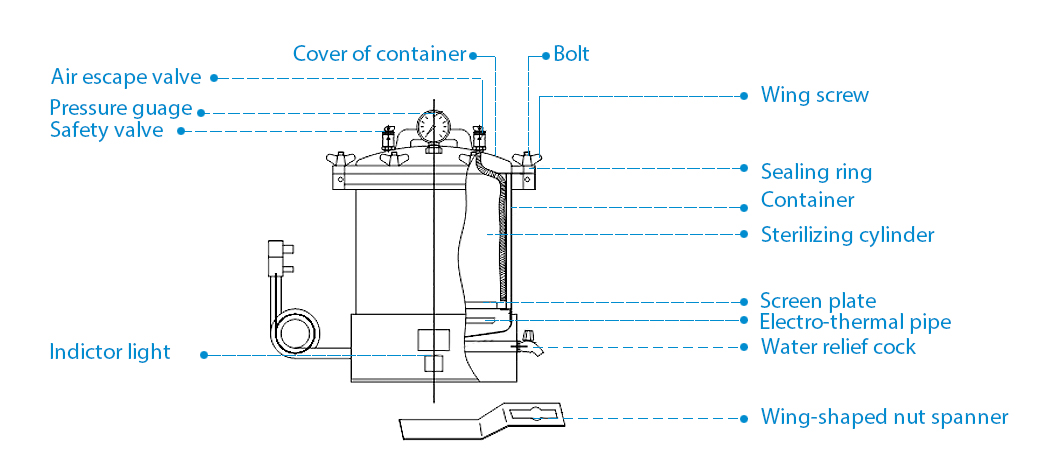

Structure Characters:

*The container and sterilizing cylinder adopt stainless steel to be pressed forming and can be acid, alkali and tensile strength proof.

*The safe valve and air escape valve on the lid of the container can release. The excessive pressure automatically when ten steam pressure exceeds 0.14 MPa. It has double safety function. Equipped with pressure gauge of MPa, convenient for customers to read.

*The product adopts immersion electrothermal tube to heat. Temperature rises up quickly. It can save energy about 50%compared with electric furnace.

Technical Data:

Guide for use:

1.Adding 3.5 litres of water in the container each time to protect the thermal tube from being burnt out.

2.Pile up: Wrap up the object and put them on the screen plate of sterilizing cylinder, left some space among parcels so as to let the steam penetrate them and ensure the sterilizing quality.

3.Put the sterilizing cylinder into the container, insert the flexible pipe which is attached to the lid of the container into the semicircle slot of the sterilizing cylinder, tighten up the screws with wing nut-spanner to ensure that the lid and the container are closely sealed.

4.Heating: Connect sterilizer to power AC 220V. After put on the switch, the indicator light starts to show the beginning of heating. At this time, open the air escape valve to let cold air escape. When the rapid steam jets out, close it. During the heating, the pressure gauge will indicate the steam pressure in sterilizer.

5.Sterilizing: Start to count the time for sterilization when the steam pressure reaches to pressure constant. If it is used for sterilization with a pressure below 0.14 MPa, when the pressure reaches the requested range, control the power switch by hand to keep the pressure constant.

6.Cooling: When the sterilization is complete, turns off the power switch.

Do not open the air escape valve on the lid of the container until the sterilizer cools down and the reading of pressure gauge returns to zero so as to avoid the boiling liquid to flow out the container or injure any person.

Navigation

Get in Touch