Get Quotes

Download Full Catalogue

Model:CNME060314B

This sterilizer is a device that uses pressure saturated steam to quickly and reliably sterilize items. It is suitable for medical and health care, scientific research, agriculture and other units. It can sterilize medical equipment, dressings, glassware, solution culture medium, etc. It is also suitable for use as steaming equipment in plateau areas and for enterprises and institutions to produce high-quality drinking water. It can also be used as a high-temperature steam source equipment.

Features:

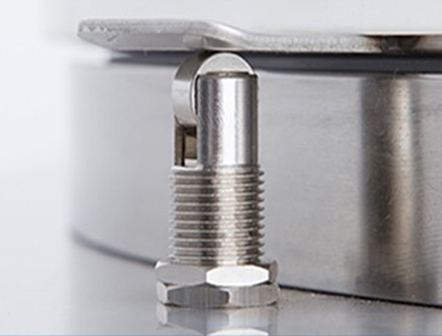

Hand wheel translation and quick opening structure

High quality stainless steel material

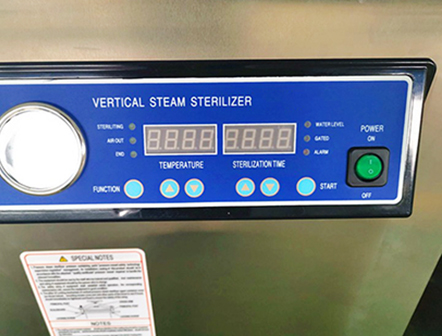

Microcomputer automatic control, arbitrary setting sterilization parameters.

Safety interlocking device

Digital display and Touch buttons

Standard test interface

Self-expanding seal

With drying function

With automatic protection function:over temperature protection; over pressure protection; low water level protection; anti dry burning.

With stainless steel bucket or basket

Buzzer reminder after sterilization, automatic stop.

Automatic discharge of cold air,automatic steam exhaust after sterilization.

Optional external printer

Specifications:

Precautions for high-pressure steam sterilizer

1. The items to be sterilized should not be placed too tightly.

2. The cold air must be fully removed, otherwise the temperature in the pot will not reach the specified temperature, affecting the sterilization effect.

3. After the sterilization is completed, the air cannot be vented and the pressure reduced, otherwise the liquid in the bottle will boil violently, wash away the bottle stopper and overflow, or even cause the container to burst. The lid can only be opened after the pressure in the sterilizer drops to the same level as the atmospheric pressure.

4. The cotton plugs of the test tubes or bottles containing the culture medium should be wrapped with oil paper or kraft paper to prevent condensed water from entering.

5. In order to ensure the sterilization effect, the sterilization effect should be checked regularly. The commonly used method is to place sulfur powder (melting point is 115°C) or benzoic acid (melting point is 120°C) in the test tube and then conduct a sterilization test. If the above substances melt, it means that the temperature in the high-pressure steam sterilizer has reached the requirement and the sterilization effect is reliable. You can also stick the adhesive tape (with a temperature-sensitive indicator) for detecting the effect of the sterilizer on the outer packaging of the items to be sterilized. If the indicator on the adhesive tape changes color, it also means that the sterilization effect is reliable.

6. There are now microcomputer-controlled high-pressure steam sterilizers. After the cold air is released, the instrument can automatically maintain constant pressure and timing. When the time is up, it will automatically cut off the power supply and sound the whistle. It is very convenient to use.

Navigation

Get in Touch