Get Quotes

Download Full Catalogue

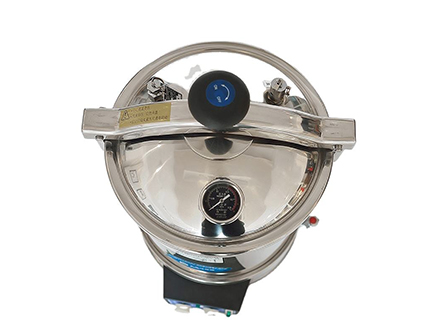

Model:CNME060304

CNMEDITECH's portable sterilizer is economically priced and doesn't take up as much space as large autoclaves. Our sterilizers make it possible for many doctors, dentists, first aid stations, hospitals and laboratories to sterilize instruments or bandages with a smaller and more portable autoclave. These sterilizers are made of high quality cast aluminum that resists rust and corrosion, ensuring years of use.

The product utilizes saturated steam to rapidly and efficiently sterilize articles. It can be used in hospitals, public health centers, health stations, clinics in factories and mines, scientific research institutes, etc, to sterilize medical equipment,surgical dressings, glass utensils, solutions, substrata. It can also be used as cooker in plateau areas and be used to make high quality drinking water in industrial and mining enterprises.

Characteristics:

Fully stainless steel structure.

Hand wheel type of quick-open door structure.

Digital display of working status, touch type key.

Automatically shut off with beep reminding after sterilization.

Electric heated.

Easy to operate, safe and reliable.

How does an autoclave work?

1. Add water and seal

First, add the appropriate amount of water to the water tank of the sterilizer. The amount of water is usually based on the manufacturer's recommendations to ensure that the amount of water is sufficient to generate steam but not too much overflow. Place the items to be sterilized (such as surgical instruments, medical dressings, etc.) on the bracket in the sterilization chamber, and then tightly close the lid of the sterilizer to ensure sealing.

2. Heat to generate steam

After power is turned on, the heating element of the sterilizer starts to work and quickly heats the water to boiling. The water turns into steam, and the steam continues to increase in the closed space, causing the temperature and pressure in the sterilization chamber to rise. Most portable autoclaves will increase the temperature to 121°C and the pressure to 15 PSI (pounds per square inch), which is the standard sterilization condition.

3. Reach and maintain high temperature and pressure

When the set high temperature and high pressure are reached, the sterilizer will maintain this condition for a period of time, usually 15 to 30 minutes. During this time, the high temperature and high pressure steam can penetrate into all parts of the instrument and completely kill all microorganisms (including bacteria, viruses, fungi and their spores). The sterilization time for different items may vary. Portable sterilizers usually have a built-in timer to accurately control the sterilization time.

4. Cooling and pressure reduction

After the sterilization time is over, the sterilizer stops heating, the interior begins to cool, and the pressure gradually decreases. Most portable sterilizers are equipped with a safety valve to manually or automatically release excess steam when necessary to avoid excessive pressure from causing danger to operators. Wait for the pressure to drop to a safe range and ensure that the temperature inside the sterilization chamber also decreases.

Technical Data:

How to clean your sterilizer?

Power off and cool down: Make sure the sterilizer is completely cooled and disconnected from the power supply.

Drain the water tank: Drain any remaining water in the sterilizer to prevent scale accumulation.

Clean the interior and water tank: Gently wipe the interior and water tank of the sterilizer with a soft cloth and warm water. Avoid using abrasive detergents to avoid damaging the inner surface. You can add a small amount of vinegar or a special detergent to remove scale, but rinse thoroughly.

Clean the seals and other parts: Wipe the seals and other moving parts with a damp cloth, and check the integrity of the seals regularly to prevent leakage.

Drying: After cleaning, dry the parts of the sterilizer in the air or wipe them with a clean soft cloth to ensure that there is no water residue.

Regular maintenance: Regularly check the safety valve, thermometer, etc. of the sterilizer to ensure that they are in good working condition.

Portable Sterilizer Safety Precautions

1. Please use distilled water to extend the service life of the sterilizer.

2. Do not touch the power cord socket with wet hands.

3. Please do not place the sterilizer on an unstable workbench, such as a shaking table, inclined surface or a vibrating position.

4. During maintenance and care, the power must be cut off first and then operated after sufficient cooling.

5. Recommendation: Clean the filter in the sterilizer regularly, wipe the inside of the sterilizer regularly, and ensure that the sterilizer is clean and tidy.

6. When working, do not move the door handle at will to avoid danger.

7.Please do not place anything on the sterilizer.

Navigation

Get in Touch